Effective Tips to Extend the Life Cycle of Cone Liners in Cone Crushers

Introduction

Cone crushers play a vital role in the mining and aggregate industries by reducing large rocks into smaller, more manageable sizes for further processing. At the heart of these machines are cone liners, which endure the brunt of the crushing process. Ensuring their longevity is crucial for maintaining crusher efficiency and minimizing operational costs. This blog aims to provide valuable insights and practical tips on extending the life cycle of cone liners in cone crushers.

Understanding Cone Liners

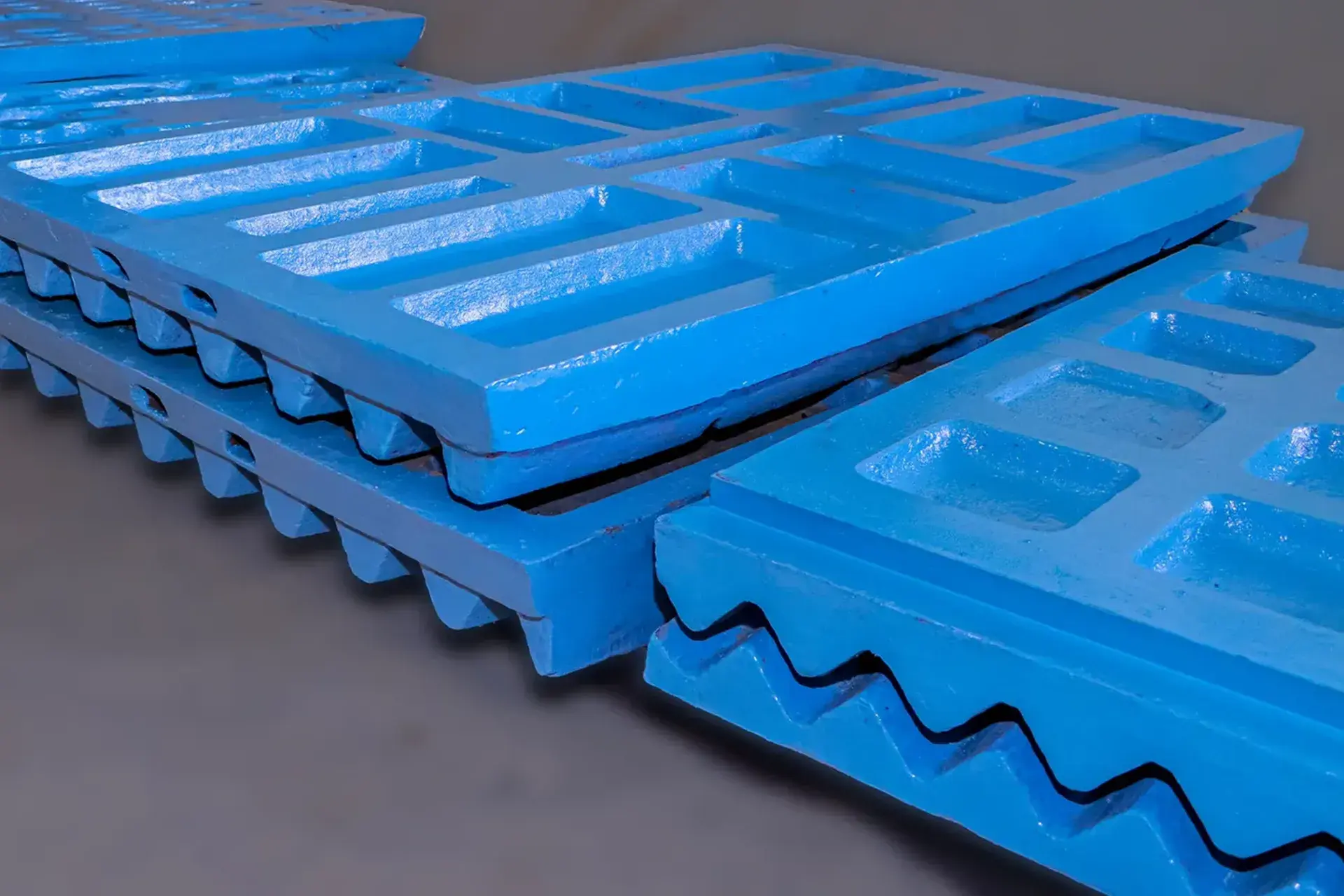

What are Cone Liners? Cone liners, also known as crusher liners, are the replaceable wear parts that protect the cone crusher’s interior. These liners come into direct contact with the material being crushed, making them essential for the crusher's operation.

Types of Cone Liners:

- Standard: Typically used for secondary crushing applications where a broad feed and larger product size are acceptable.

- Medium: Suitable for finer crushing applications, providing a balanced approach between feed size and final product.

- Short Head: Used for ultra-fine crushing applications, where precise control over the final product size is required.

Factors Affecting Cone Liner Life Cycle

Material Hardness: The hardness of the material being crushed significantly impacts

the wear rate of cone liners. Harder materials cause faster wear, requiring more frequent

replacements.

Feed Size: Oversized feed can lead to uneven wear and increased stress on the liners.

Properly sized feed ensures even wear distribution and extends liner life.

Crusher Settings: Incorrect crusher settings, such as improper closed-side settings

or excessive horsepower, can lead to premature liner wear. Optimal settings ensure efficient

crushing and prolong liner lifespan.

Improper Usage and Maintenance: Inadequate maintenance practices and improper usage,

such as overloading the crusher or using incorrect liners, can significantly shorten the

life cycle of cone liners. A notable example involved a quarry operation that experienced

frequent liner replacements due to overloading, leading to increased operational costs and

downtime.

Maintenance Tips for Extending Cone Liner Life

Daily Maintenance:

- Visual Inspections: Conduct regular visual inspections to check for signs of wear, cracks, and loose fittings.

- Lubrication: Ensure that all moving parts are adequately lubricated to reduce friction and wear.

Weekly Maintenance:

- Tightening Bolts: Check and tighten all bolts and screws to ensure the liners are securely fastened.

- Wear Monitoring: Monitor wear patterns and thickness to predict when replacements will be needed.

Monthly Maintenance:

- Detailed Inspections: Perform comprehensive inspections to identify significant wear and determine if liner replacements are necessary.

- Alignment Checks: Ensure that the liners are correctly aligned to prevent uneven wear.

- Timely Replacements: Replacing cone liners before they become excessively worn prevents damage to the crusher and maintains efficiency. Keeping spare liners on hand minimizes downtime.

Advanced Maintenance Practices

Wear-Resistant Materials: Utilizing wear-resistant materials such as tungsten carbide

or specialized alloys can significantly extend the life cycle of cone liners. These

materials offer superior resistance to abrasion and impact.

Monitoring Systems: Implementing monitoring systems that track wear in real-time can

help in planning maintenance schedules more effectively. Technologies such as wear

indicators and sensors provide valuable data for proactive maintenance.

Protective Coatings: Applying protective coatings to cone liners can enhance their

resistance to wear and corrosion. These coatings are particularly useful in harsh operating

environments.

Industry Standards: Adhering to industry best practices and standards ensures that

maintenance is performed correctly, enhancing the efficiency and lifespan of cone liners.

Following guidelines from manufacturers and industry bodies can lead to improved performance

and reduced maintenance costs.

Benefits of Proper Maintenance

Cost Savings: Proper maintenance reduces the frequency of liner replacements,

resulting in significant cost savings. It also minimizes downtime, ensuring continuous

production.

Improved Efficiency: Well-maintained cone liners enhance the crushing efficiency of

the cone crusher, leading to better product quality and higher throughput.

Increased Safety: Proper maintenance ensures that the cone liners and other crusher

components operate safely, reducing the risk of accidents and injuries.

Long-Term Advantages: For businesses in the mining and aggregate industries,

investing in the maintenance of cone liners translates to long-term benefits such as

increased equipment lifespan, better resource utilization, and improved overall

profitability.

Conclusion

Maintaining cone liners in cone crushers is crucial for optimizing performance and ensuring longevity. Regular inspections, timely replacements, and the use of advanced maintenance practices can significantly enhance the efficiency and lifespan of cone liners. By implementing the tips and practices shared in this blog, businesses can achieve better crusher performance and enjoy long-term benefits.

For further assistance or to learn more about our products and services, contact Wear Steels Pvt Ltd today. Reach out to our team for expert advice and support.

Latest Blogs

Effective Maintenance of Jaw Plates in Jaw Crushers: Essential Tips and Practices

Jaw crushers are indispensable equipment in the mining and construction industries, known for their role in reducing large rocks into smaller, more manageable sizes. Central to the functionality of these powerful ....

Effective Tips to Extend the Life Cycle of Cone Liners in Cone Crushers

Cone crushers play a vital role in the mining and aggregate industries by reducing large rocks into smaller, more manageable sizes for further processing. At the heart of these machines are cone liners, which endure the brunt of ....

The Future of Sustainable Manufacturing: Exploring Green Casting Techniques

Green casting represents a transformative shift in manufacturing, aiming to minimize environmental impact through eco-friendly materials and processes. This approach is crucial for reducing the industry's ....

Download our brochure to view our product portflio!

We're here to help

Fill out the form to reach us!