The Future of Sustainable Manufacturing: Exploring Green Casting Techniques

Introduction

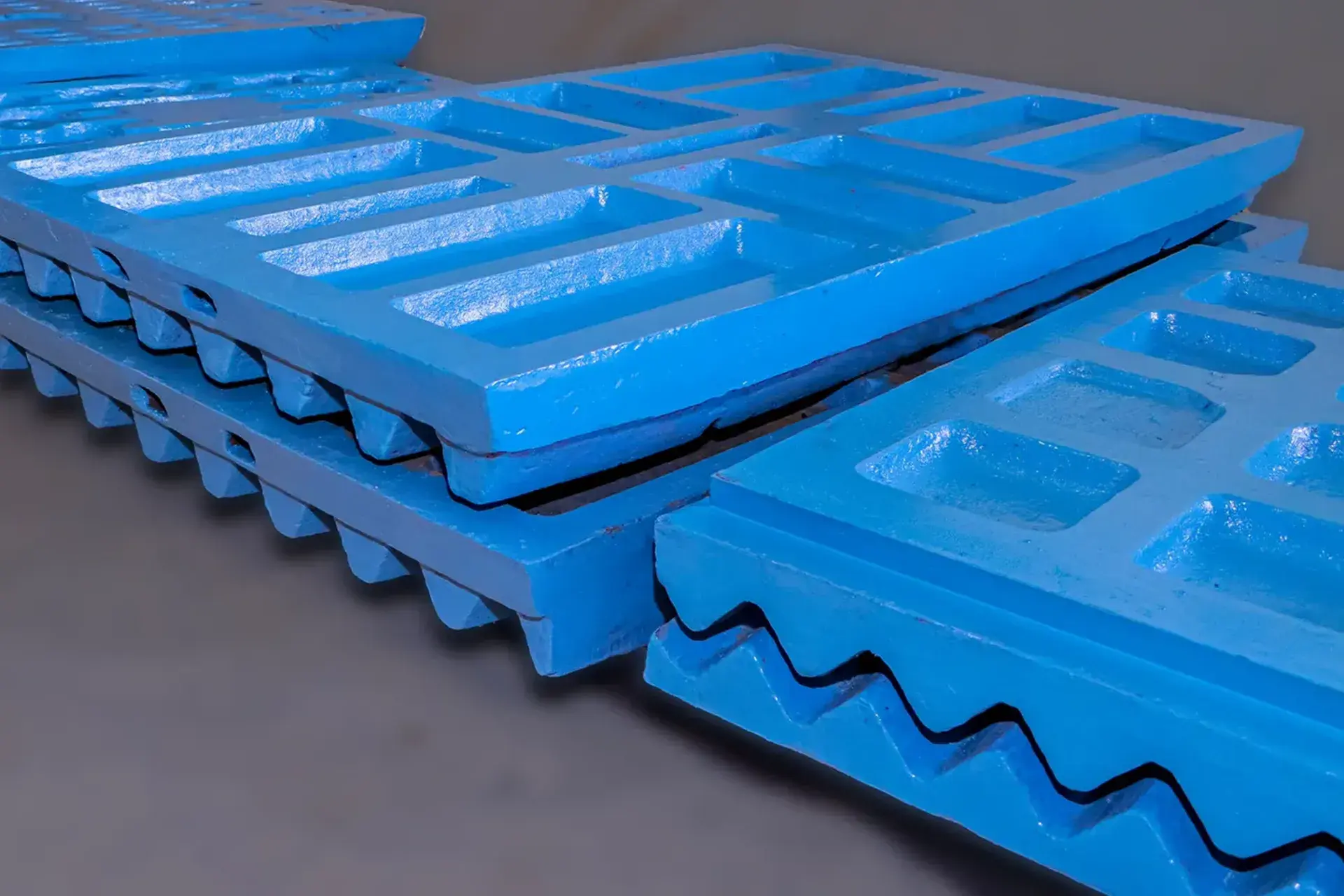

Green casting represents a transformative shift in manufacturing, aiming to minimize environmental impact through eco-friendly materials and processes. This approach is crucial for reducing the industry's carbon footprint and promoting sustainable development. Green casting not only benefits the environment but also offers economic and health advantages for manufacturers. This blog aims to educate readers on green casting techniques and their benefits, encouraging the adoption of sustainable practices in the industry.

Understanding Green Casting

Defining Green Casting: Green casting refers to manufacturing processes that prioritize sustainability by using eco-friendly materials and energy-efficient methods. Unlike traditional casting, which often relies on high-energy consumption and non-renewable resources, green casting aims to reduce environmental impact through innovative techniques.

Principles of Green Casting:

- Eco-Friendly Materials: Utilizing biodegradable sand molds and recycled materials to minimize waste.

- Energy Efficiency: Implementing processes that require less energy, thereby reducing carbon emissions.

Environmental Impact: Traditional casting methods contribute significantly to pollution and waste. Green casting offers a sustainable alternative by reducing emissions, conserving resources, and promoting the use of renewable materials.

Key Techniques in Green Casting

Biodegradable Sand Molds: Using biodegradable sand molds

helps reduce the environmental footprint of the casting process.

These molds decompose naturally, eliminating the need for waste

disposal.

Recycled Materials: Incorporating recycled materials into

the casting process minimizes waste and conserves natural

resources. This technique not only supports sustainability but

also reduces production costs.

Energy-Efficient Processes: Energy-efficient processes,

such as using renewable energy sources and advanced

manufacturing technologies, lower energy consumption and

emissions. For instance, electric arc furnaces powered by

renewable energy significantly reduce the carbon footprint

compared to traditional blast furnaces.

Case Studies: Several companies have successfully

implemented green casting techniques. For example, a foundry in

Germany reduced its energy consumption by 30% by switching to

electric arc furnaces and using recycled materials in its

casting process. Another case involved a U.S. manufacturer that

achieved zero waste by adopting biodegradable molds and

efficient waste recycling systems.

Benefits of Green Casting

Environmental Benefits: Green casting significantly

reduces the carbon footprint and minimizes waste, contributing

to a cleaner and more sustainable environment. By using

eco-friendly materials and processes, manufacturers can help

mitigate the effects of climate change.

Economic Advantages: Green casting offers cost savings

through reduced energy consumption and material reuse. Companies

can also benefit from potential tax incentives and grants for

adopting sustainable practices.

Workplace Safety and Health: Implementing green casting

techniques improves workplace safety and health by reducing

exposure to hazardous materials and pollutants. This leads to a

safer working environment and can decrease health-related costs

for employers.

Challenges and Solutions in Green Casting

Practical Solutions:

- Investment in Technology: Investing in advanced technologies and equipment can help overcome initial cost barriers and improve efficiency.

- Training and Education: Providing training and resources to employees can facilitate the transition to green casting methods.

- Collaboration: Partnering with other companies and industry bodies can promote knowledge sharing and innovation.

Role of Technological Advancements: Technological advancements, such as AI-driven monitoring systems and advanced recycling techniques, play a crucial role in addressing the challenges of green casting. Innovations in material science and manufacturing processes continue to drive the industry towards more sustainable practices.

The Future of Green Casting

Future Trends: The future of green casting looks

promising, with ongoing research and development focused on

improving sustainability and efficiency. Emerging technologies,

such as 3D printing and nanomaterials, are expected to

revolutionize the industry.

Industry Standards: As awareness of environmental issues

grows, green casting is likely to become the standard in

manufacturing. Industry standards and regulations will

increasingly emphasize sustainability, driving more companies to

adopt eco-friendly practices.

Ongoing Research and Initiatives: Research institutions

and industry organizations are actively exploring new green

casting methods and materials. Initiatives aimed at reducing the

environmental impact of manufacturing processes are gaining

momentum, paving the way for a more sustainable future.

Conclusion

Green casting techniques offer a sustainable alternative to traditional casting methods, providing significant environmental, economic, and health benefits. By adopting these techniques, manufacturers can reduce their carbon footprint, lower production costs, and create safer workplaces. The future of green casting is bright, with ongoing research and technological advancements promising even greater improvements in sustainability.

If you're interested in learning more about green casting or need assistance implementing these techniques in your manufacturing process, contact Wear Steels Pvt Ltd today. Reach out to our team for expert advice and support.

Latest Blogs

Effective Maintenance of Jaw Plates in Jaw Crushers: Essential Tips and Practices

Jaw crushers are indispensable equipment in the mining and construction industries, known for their role in reducing large rocks into smaller, more manageable sizes. Central to the functionality of these powerful ....

Effective Tips to Extend the Life Cycle of Cone Liners in Cone Crushers

Cone crushers play a vital role in the mining and aggregate industries by reducing large rocks into smaller, more manageable sizes for further processing. At the heart of these machines are cone liners, which endure the brunt of ....

The Future of Sustainable Manufacturing: Exploring Green Casting Techniques

Green casting represents a transformative shift in manufacturing, aiming to minimize environmental impact through eco-friendly materials and processes. This approach is crucial for reducing the industry's ....

Download our brochure to view our product portflio!

We're here to help

Fill out the form to reach us!