The Importance of Jaw Plates in Crushing Industry: Durability and Performance

Introduction

In the crushing industry, jaw plates play a vital role in breaking down rocks, ores, and minerals into smaller pieces for further processing. Whether in mining, construction, or quarrying, the efficiency of a jaw crusher depends largely on the durability and performance of its jaw plates. At Wear Steels, we understand the significance of high-quality jaw plates and provide robust, wear-resistant solutions to enhance crushing efficiency and reduce downtime. This blog explores the importance of jaw plates, their types, materials, and how to ensure their long-lasting performance.

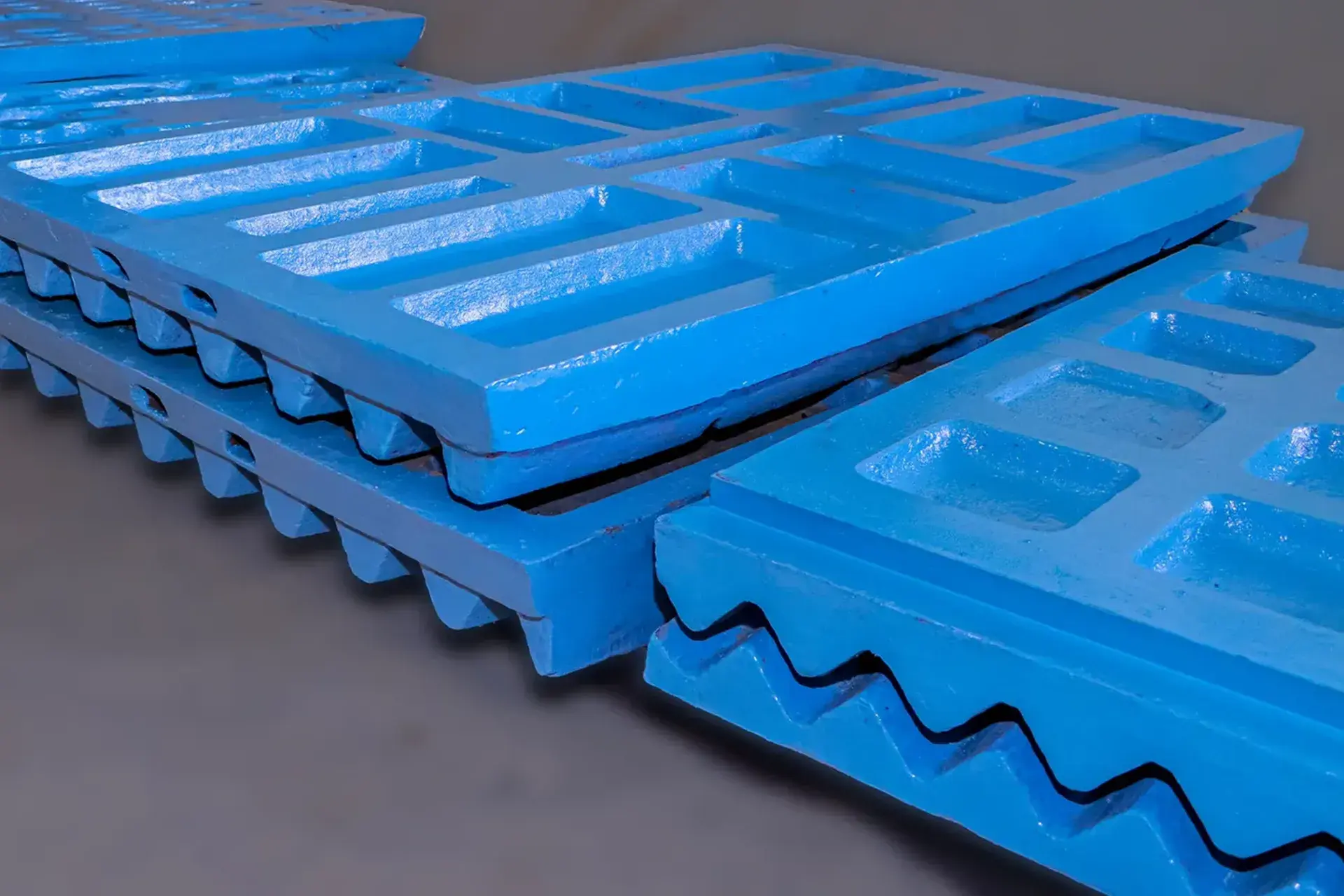

What Are Jaw Plates?

Jaw plates are the primary wear parts of a jaw crusher. These metallic plates are fixed to the jaw of the crusher, creating a compression mechanism to crush materials like stones, ores, and concrete.

A jaw crusher has two types of plates:

- Fixed Jaw Plate: Stationary and mounted to the crusher frame.

- Movable Jaw Plate: Moves in a reciprocating motion to crush materials.

The crushing action occurs when the movable jaw plate pushes the material against the fixed jaw plate. Over time, these plates wear out, affecting performance. That’s why choosing high-quality, durable jaw plates is essential for an efficient crushing process.

Types of Jaw Plates

Not all jaw plates are the same. They come in different designs and materials based on the type of rock or ore being crushed.

1. Manganese Steel Jaw Plates

- Most commonly used due to high impact resistance.

- Offers good durability under extreme crushing conditions.

- Available in various manganese content levels (12-14%, 16-18%, 21%).

2. Alloy Steel Jaw Plates

- Ideal for crushing harder materials like granite or quartz.

- Resistant to extreme abrasion but slightly more brittle than manganese steel.

3. Tungsten Carbide Jaw Plates

- Highly durable and best suited for laboratory crushers.

- Expensive but offers extended wear life.

Choosing the right jaw plate depends on the type of rock, crusher settings, and desired output size.

Why Jaw Plate Durability Matters?

- ✔ Increased downtime due to frequent replacements.

- ✔ Reduced crushing efficiency, leading to higher power consumption.

- ✔ Poor product quality and inconsistent output sizes.

Durability is crucial because worn-out jaw plates can lead to:

- ✔ Long-lasting wear resistance.

- ✔ Improved crushing efficiency.

- ✔ Cost savings on maintenance and replacements.

Using high-performance jaw plates from Wear Steels ensures:

Factors Affecting Jaw Plate Performance

1. Material Hardness and Composition

- Harder materials wear out jaw plates faster.

- Manganese steel adjusts its hardness based on impact levels, increasing lifespan.

2. Crusher Settings & Feed Material

- Incorrect feed size can cause uneven wear.

- Too much small material leads to unnecessary wear on the jaw plates.

3. Crushing Force & Pressure

- Excessive force can lead to cracks and fractures.

- Proper alignment and crusher settings can help reduce stress on jaw plates.

4. Maintenance & Regular Inspection

- Scheduled inspections prevent sudden failures.

- Reversing jaw plates periodically ensures even wear.

At Wear Steels, our jaw plates are designed for maximum durability, reducing wear and extending the crusher’s lifespan.

Tips to Increase Jaw Plate Life

- ✔ Choose the right material for your application.

- ✔ Ensure proper crusher settings to avoid unnecessary stress.

- ✔ Avoid overloading the crusher with large-sized rocks.

- ✔ Reverse jaw plates to distribute wear evenly.

- ✔ Regularly monitor wear patterns and replace when necessary.

Why Choose Wear Steels for Jaw Plates?

At Wear Steels, we manufacture high-quality, wear-resistant jaw plates for all types of crushers. Our products offer:

- ✔ Premium-grade manganese steel for high-impact resistance.

- ✔ Custom-made solutions to match specific crushing needs.

- ✔ Competitive pricing with exceptional durability.

- ✔ Proven performance in mining, construction, and quarrying industries.

For reliable jaw plates that improve efficiency and reduce downtime, trust Wear Steels!

Factors Affecting Jaw Plate Performance

1. How long do jaw plates last in a crusher?

The lifespan depends on the material being crushed, the type of jaw plate used, and crusher settings.

2. How do I know when to replace my jaw plates?

If you notice uneven wear, cracks, reduced crushing efficiency, or excessive vibration, it’s time to replace the jaw plates.

3. Can jaw plates be customized for specific crushers?

Yes! Wear Steels provides customized jaw plates designed for different crusher brands and applications.

4. What is the best material for jaw plates?

Manganese steel is the most common choice, but alloy steel and tungsten carbide are also used based on the hardness of the material being crushed.

5. How can I extend the life of my jaw plates?

Regular maintenance, proper crusher settings, and selecting the right jaw plate material can significantly increase lifespan.

Conclusion

Jaw plates are essential components in the crushing industry, impacting efficiency, productivity, and operating costs. Investing in durable, high-quality jaw plates can make a huge difference in performance. At Wear Steels, we provide reliable, wear-resistant jaw plates designed to last longer and perform better. Contact us today for the best jaw plates for your crushers!

Latest Blogs

Download our brochure to view our product portflio!

We're here to help

Fill out the form to reach us!