The Importance of Jaw Plates in Crushing Industry: Durability and Performance

Introduction

A jaw crusher is a key piece of equipment in industries like

mining, construction, and aggregates, used to break down large

rocks into smaller, manageable sizes. To keep the jaw crusher

working efficiently, various components need to be durable and

wear-resistant. Among these, cheek plates and side plates play

an important role in enhancing crusher performance and extending

its lifespan.

At Wear Steels, we manufacture high-quality, wear-resistant

cheek plates and side plates to keep your jaw crushers running

efficiently with minimal downtime. In this blog, we’ll explore

how these components work, their differences, and how they

contribute to better crusher efficiency.

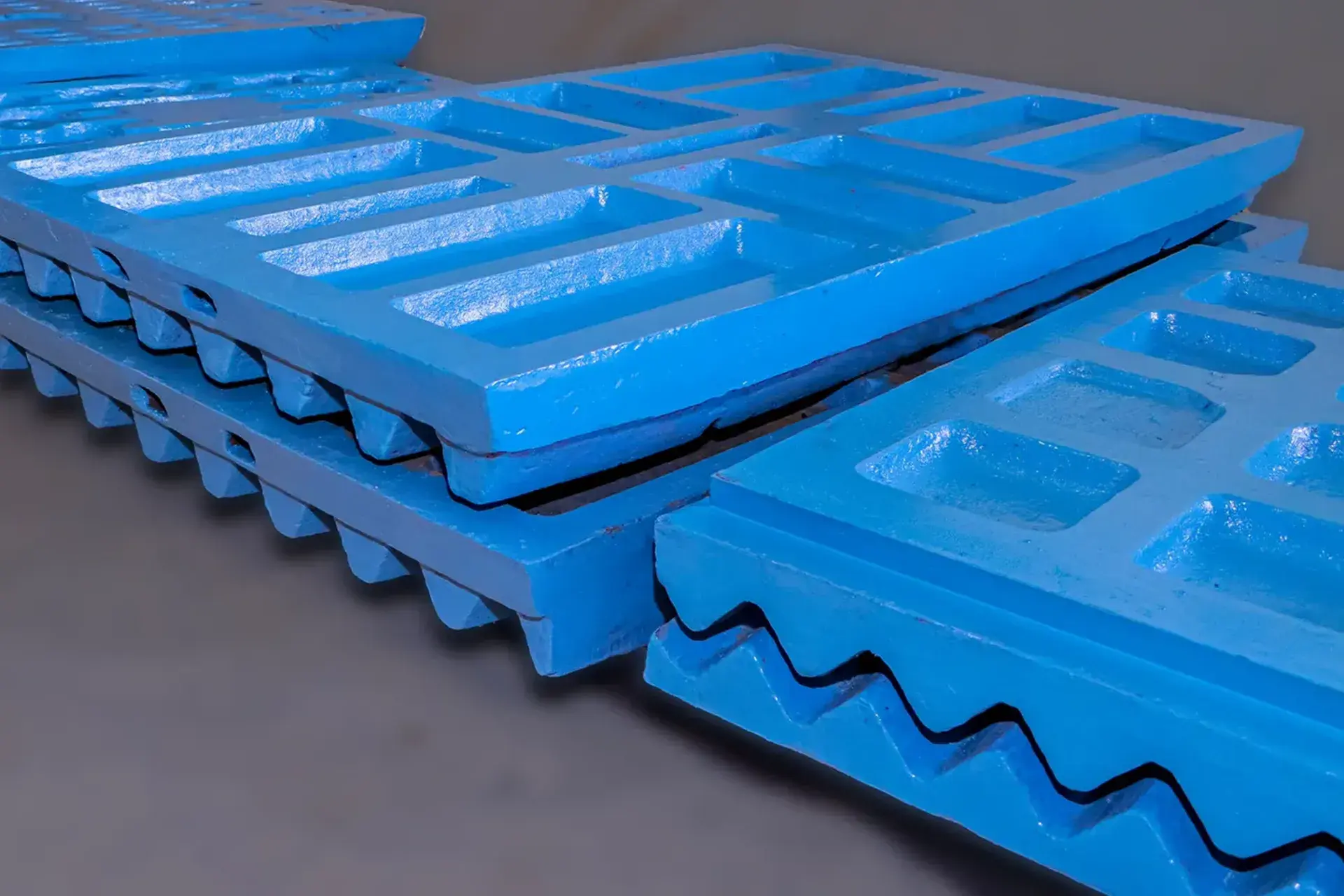

What Are Cheek Plates?

Cheek plates are the protective liners placed on the sides of the crushing chamber in a jaw crusher. Their main function is to protect the crusher frame from excessive wear caused by continuous impact and friction with rocks and minerals.

Key Functions of Cheek Plates:

- ✔ Protects the crusher body from direct material impact

- ✔ Reduces maintenance costs by preventing wear on the crusher frame

- ✔ Increases jaw plate lifespan by absorbing impact

- ✔ Enhances crushing efficiency by ensuring smooth material flow

Materials Used for Cheek Plates:

- High Manganese Steel – Provides excellent wear resistance

- Alloy Steel – Improves durability under extreme crushing conditions

- Hardened Steel – Best suited for heavy-duty applications

Applications of Side Plates:

- Mining Industry – Crushing hard rocks and ores

- Aggregate Plants – Breaking down stones for construction

- Quarrying Operations – Processing large materials efficiently

What Are Side Plates?

Side plates, also known as jaw crusher body liners, are fitted along the sides of the crusher frame. Their purpose is to reinforce the crusher structure, prevent excess stress on the frame, and reduce the impact of heavy loads.

Key Functions of Cheek Plates:

- ✔ Absorbs impact and prevents frame damage

- ✔ Provides structural stability to support jaw plates

- ✔ Improves overall efficiency by maintaining crusher alignment

- ✔ Reduces stress on other components, extending their lifespan

Materials Used for Cheek Plates:

- High Tensile Steel – Ensures durability under extreme pressure

- Heat-Treated Alloy Steel – Enhances wear resistance

Applications of Side Plates:

- Jaw Crushers in Mining – Handles continuous heavy loads

- Rock and Mineral Processing Plants – Supports high-impact crushing

- Recycling Plants – Crushes concrete, asphalt, and industrial waste

Cheek Plates vs. Side Plates: Key Differences

| Feature | Cheek Plates | Side Plates |

| Location | Inside the crushing chamber | Along the sides of the crusher frame |

| Function | Protects jaw plates and prevents frame wear | Supports the crusher structure and enhances stability |

| Material | High manganese steel, alloy steel | High tensile steel, heat-treated alloy |

| Wear Resistance | High | Very High |

| Maintenance | Needs regular inspection | Requires less frequent replacement |

While both cheek plates and side plates are essential for crusher durability and efficiency, they serve different roles. Cheek plates protect the frame from direct impact, while side plates reinforce the structure and provide stability.

How Cheek Plates and Side Plates Enhance Jaw Crusher Efficiency

1. Reducing Wear and Tear on Crusher Components

Without cheek plates and side plates, the crusher frame would wear out quickly, leading to frequent breakdowns and high maintenance costs.

2. Improving Crushing Efficiency

By absorbing the impact of material and keeping the jaw plates aligned, these plates ensure better material flow, leading to efficient crushing and reduced power consumption.

3. Enhancing Durability and Longevity

High-quality cheek plates and side plates extend the life of jaw crushers, reducing downtime and boosting productivity.

4. Ensuring Smooth Crusher Operation

These plates help prevent the misalignment of jaw plates, allowing the crusher to function smoothly without sudden stops or blockages.

5. Reducing Maintenance Costs

Replacing cheek plates and side plates at the right time prevents expensive damage to other crusher components, saving money in the long run.

How to Choose the Right Cheek Plates and Side Plates?

- ✔ Check the Material : Choose high-manganese steel or alloy steel for better wear resistance.

- ✔ Ensure Proper Fit : Buy plates designed for your specific crusher model.

- ✔ Consider the Crushing Application : Harder materials need stronger, heat-treated plates.

- ✔ Invest in Quality : Always purchase from a trusted supplier like Wear Steels.

By using high-quality components, you can increase efficiency, reduce maintenance costs, and extend the life of your crusher.

Maintenance Tips for Cheek Plates and Side Plates

- ✔ Regular Inspection : Look for signs of excessive wear, cracks, or misalignment.

- ✔ Timely Replacement : Don’t wait for total wear-out—replace before damage occurs.

- ✔ Use Genuine Parts : Always source from trusted manufacturers like Wear Steels.

- ✔ Keep Crusher Settings Optimized : Ensure proper jaw alignment to prevent unnecessary stress.

By following these tips, you can extend the lifespan of your crusher components and maintain optimal performance.

FAQs: Toggle Plates vs. Toggle Sheets

1. How often should cheek plates and side plates be replaced?

Cheek plates need replacement when they show significant wear, cracks, or misalignment. Side plates last longer but should be checked periodically for stress fractures.

2. Can I use the same material for cheek plates and side plates?

It depends on the application. Cheek plates require high impact resistance, while side plates need structural strength. High-manganese steel is ideal for cheek plates, while alloy steel works best for side plates.

3. How do cheek plates and side plates impact jaw crusher efficiency?

By reducing wear, improving material flow, and protecting the crusher frame, these plates enhance efficiency, reduce maintenance, and extend crusher life.

4. What happens if I don’t replace worn cheek plates?

A worn-out cheek plate can cause frame damage, reduce crushing efficiency, and increase downtime. Timely replacement is essential.

5. Where can I buy high-quality cheek plates and side plates?

You can get premium, wear-resistant cheek plates and side plates at Wear Steels. We provide customized solutions for all types of jaw crushers!

Conclusion

Both cheek plates and side plates are crucial components in a

jaw crusher. While cheek plates protect the frame from wear,

side plates reinforce the structure and improve stability.

For high-performance, wear-resistant crusher parts, trust Wear

Steels! Visit our website to explore our range of crusher wear

parts.

Latest Blogs

Download our brochure to view our product portflio!

We're here to help

Fill out the form to reach us!