Toggle Plates vs. Toggle Sheets: Key Differences and Applications

Introduction

In the crushing industry, jaw crushers are one of the most

important machines used to break down large rocks into smaller,

manageable sizes. Within these crushers, toggle plates and

toggle sheets play crucial roles in ensuring efficient crushing

operations. But what exactly are these components, and how do

they differ?

If you are involved in mining, construction, or aggregate

processing, understanding the difference between toggle plates

and toggle sheets is essential to improve performance, reduce

wear, and ensure a longer lifespan for your crushing equipment.

At Wear Steels, we provide high-quality, wear-resistant toggle

plates and toggle sheets designed to enhance crusher efficiency.

What is a Toggle Plate?

A toggle plate is a safety component in a jaw crusher that serves multiple purposes:

A jaw crusher has two types of plates:

- ✔ Absorbs excessive force during crushing operations

- ✔ Prevents damage to other crusher parts

- ✔ Allows movement of the jaw for effective crushing

The toggle plate acts like a fuse, breaking or bending when excessive force is applied to prevent serious damage to the jaw crusher.

Key Features of Toggle Plates

- Made of high-strength steel or alloy

- Acts as a safety mechanism for jaw crushers

- Absorbs impact and reduces shock loads

- Can be replaced easily when worn out

Applications of Toggle Plates

- Jaw Crushers - Provides movement and protects against overload

- Mining Operations - Ensures continuous performance under extreme pressure

- Construction and Aggregates - Used in heavy-duty crushing applications

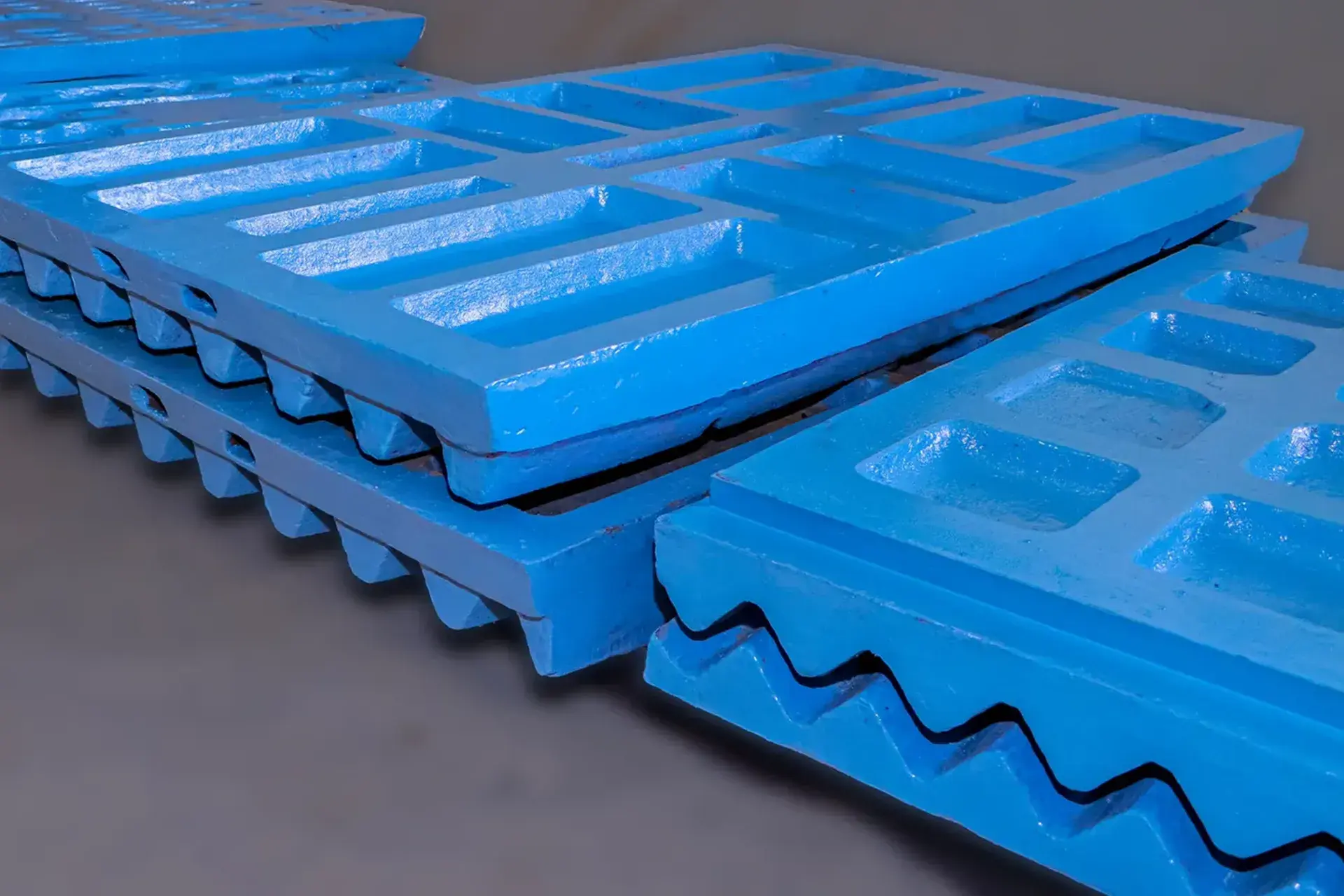

What is a Toggle Sheet?

A toggle sheet is a liner or backing plate positioned between the toggle plate and the crusher frame. It acts as a protective layer, reducing direct wear and friction between components.

Key Features of Toggle Sheets

- Acts as a cushion between toggle plate and frame

- Made from wear-resistant materials like manganese or hardened steel

- Protects the crusher structure from excessive wear

- Ensures smooth jaw movement

Applications of Toggle Sheets

- Jaw Crushers - Prevents frame wear and increases lifespan

- Heavy-Duty Crushing Equipment - Enhances durability of crusher components

- Mining & Quarrying - Reduces maintenance and downtime

Key Differences Between Toggle Plates and Toggle Sheets

| Feature | Toggle Plate | Toggle Sheet |

| Function | Controls jaw movement and protects against overload | Acts as a protective layer between toggle plate and frame |

| Material | High-strength steel, manganese, or alloy | Wear-resistant materials like hardened steel |

| Primary Role | Absorbs impact and prevents crusher damage | Reduces friction and wear between crusher components |

| Replacement | Breaks under excess force and requires replacement | Designed to last longer but needs periodic checks |

| Usage | Found in all jaw crushers | Used in crushers that handle heavy loads |

Both components work together to ensure that the crusher operates efficiently while minimizing wear and tear.

Why Are High-Quality Toggle Plates and Toggle Sheets Important?

Using low-quality or worn-out toggle plates and toggle sheets can lead to:

- Increased crusher downtime

- Higher maintenance costs

- Reduced crushing efficiency

- Risk of severe equipment damage

That’s why Wear Steels, provides premium-quality, wear-resistant toggle plates and toggle sheets to enhance the lifespan and performance of your jaw crushers.

How to Choose the Right Toggle Plate and Toggle Sheet?

When selecting toggle plates and toggle sheets, consider the following:

- ✔ Material Type: Choose high-manganese or alloy steel for durability

- ✔ Crusher Type: Ensure compatibility with your jaw crusher model

- ✔ Crushing Application: Consider the hardness of the material being crushed

- ✔ Manufacturer Reputation: Buy from trusted suppliers like Wear Steels

By investing in the right toggle components, you can increase efficiency, reduce maintenance costs, and extend crusher life.

Maintenance Tips for Toggle Plates and Toggle Sheets

- Regularly inspect for wear and cracks

- Replace toggle plates when they show signs of bending or breaking

- Ensure toggle sheets remain intact to prevent frame wear

- Use high-quality replacements from Wear Steels for long-term performance

FAQs: Toggle Plates vs. Toggle Sheets

1. What happens if the toggle plate in a jaw crusher breaks?

If the toggle plate breaks, the jaw crusher will stop functioning properly. It acts as a safety mechanism, preventing severe damage to other parts of the crusher. Immediate replacement is required.

2. How often should toggle plates and toggle sheets be replaced?

Toggle plates should be replaced whenever cracks or bending are observed. Toggle sheets last longer but should be checked regularly for wear and alignment issues.

3. Can toggle sheets be reused after wear?

It depends on the extent of the wear. Minor surface wear can sometimes be adjusted, but severely worn toggle sheets should be replaced to prevent damage to the crusher frame.

4. How do I know if my toggle plate is worn out?

Look for visible cracks, bending, or excessive wear. If the jaw crusher isn’t operating smoothly or making unusual noises, check the toggle plate immediately.

5. Where can I buy high-quality toggle plates and toggle sheets?

You can get premium, wear-resistant toggle plates and toggle sheets at Wear Steels. We offer customized solutions for all types of jaw crushers!

Conclusion

Both toggle plates and toggle sheets are crucial components in

a jaw crusher. While the toggle plate controls jaw movement

and protects the crusher, the toggle sheet reduces wear and

extends the life of critical components.

For high-performance, wear-resistant crusher parts, trust Wear

Steels! Visit our website to explore our range of crusher wear

parts.

Latest Blogs

Download our brochure to view our product portflio!

We're here to help

Fill out the form to reach us!